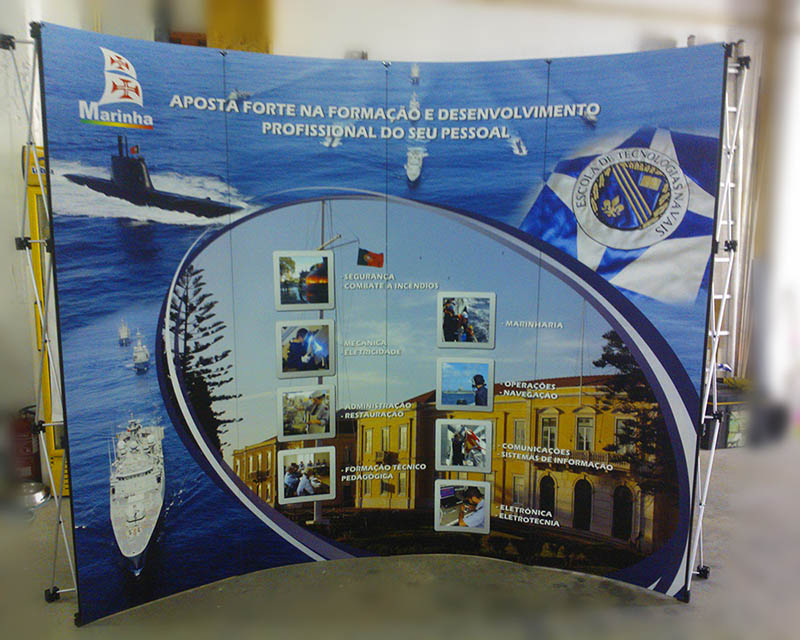

As they ask for print works, often our clients also need, included in the communication they are doing, outdoor displays, placards, shop and stand decoration, car decoration, collaborator's clothes, signalectics and so on.

Taking care of the printing work, we are in a good position to do these other works, as we have the graphic files already corrected and configured by our preprinting and graphic design department. Supplying the large format services, we ease the client's tasks of contact and monitoring – giving also a wider employ to our technical capacity.

The printing plotter

is a giant inkjet printer. It is roll fed, so that it can print very long

images. As every one of our big printers, the print plotter is commander by a

dedicated computer, a Raster Image Processor (RIP).

The printing plotter

is a giant inkjet printer. It is roll fed, so that it can print very long

images. As every one of our big printers, the print plotter is commander by a

dedicated computer, a Raster Image Processor (RIP).

Cutting plotter: a cutting blade is under control of a computer to execute cuts and folds in a sticker film.

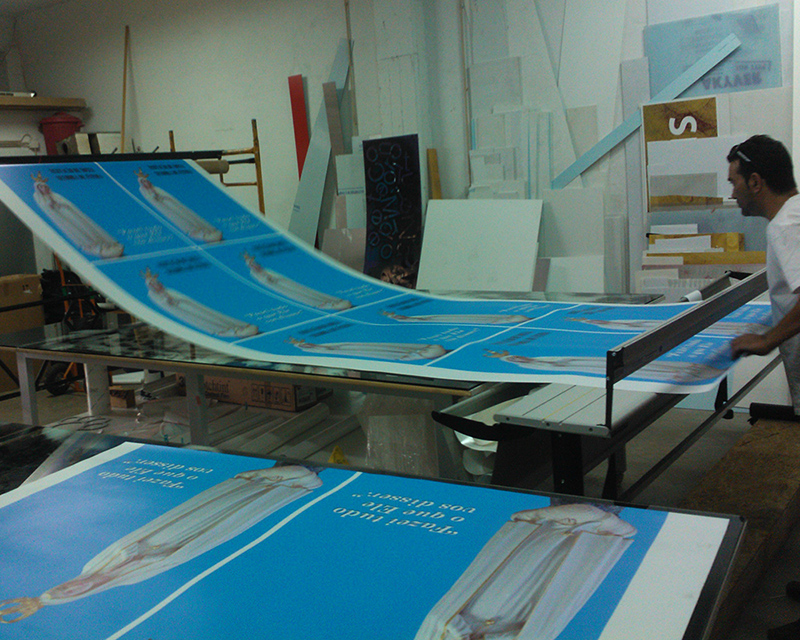

Large format uses giant inkjet printers called plotters. Our main plotter is a Roland with an opening of 1.60 m. The printing heads run their course along the opening, which is the limiting factor about the width of the roll we can use. The printing work, on the contrary, can be very long. These machines are quite slow, but the pieces to print are usually unique or a very small number.

The media we use can vary with the function of the piece – from the vinyl film to plastic canvas to the rollups, from the sticker film to car decoration to semitransparent perforated canvas for shop and car windows. The inks are also different, when they are meant to endure the outdoors sun.

When the pieces are even larger than the plotter's opening, they can be divided in tiles later mouted in the local with precision. This operations require art and experience. The printed pieces can be directly mounted at the destination or glued – in the case of canvases, stuck with wires and grommets – or they can be mounted in supporting surfaces like PVC, wood, cardboard or acrylic plates. It's common for the pieces to need to be protected with transparent sticker film and for that we have a large laminator.

The milling cutter is able to make letters and other 3D pieces.

For the letters and drawings glued to shop windows or cars, we use the Graphitec cutting plotter. It does very precise cuts under computer command. It is able to cut also pictures previously printed in the plotter.

Another discipline, another machine is the Maxgraver MG-1530 milling cutter, requiring very specific know-how. Also computer controlled, it drills and models pieces, in acrylic, wood, PVC, etc., to point-of-sales displays, stand or shop decoration. Everything is incorporated into the final montage.

It's important to know the various materials and methods, their advantages, shortcomings and costs. To be able to counsel our client about the best choices helps to get the best final quality at the best prices.